OPTIMIZE YOUR ORDER FULFILLMENT

19 ideas brands can use to cut fulfillment costs

-4.png?width=52&height=52&name=Untitled%20design%20(5)-4.png)

-Dec-20-2023-10-40-17-4769-AM.png?width=52&height=52&name=Untitled%20design%20(4)-Dec-20-2023-10-40-17-4769-AM.png)

Introduction

Operations professionals are under the gun more than ever to deliver highly efficient warehouse and shipping services, while still ensuring product integrity, happy customers and 100% regulatory compliance.

It’s a tall order to prioritize cost control in order fulfillment, particularly for products with special requirements like temperature control, expiration date monitoring, kitting requirements, and persnickety customers. But that’s the reality you live in.

With that in mind, we’ve compiled 19 ideas to help brands cut fulfillment costs to achieve a fitter bottom line. We’ll explore savings opportunities in 4 areas: 1) Planning, 2) Pick/pack operations, 3) Parcel shipping, and 4) People management.

Frankly, some of the ideas you’ve already implemented, and others won’t be right for you. But spotting just one or two implementable strategies can make this 10–15 minute read worth it 1,000 times over.

Let’s get started.

- Introduction

- Chapter I: Share sales forecasts to improve labor planning

- Chapter II: Conduct periodic distribution network modeling

- Chapter III: Integrate B2C and B2B fulfillment operations

- Chapter IV: Embrace data

- Chapter V: Optimize your picking strategy

- Chapter VI: Deploy basic automation to reduce labor costs

- Chapter VII: Use cobots for transporting goods in the warehouse

- Chapter VIII Improve slotting to reduce labor expenses

- Chapter IX Automate inventory counts with drones

- Chapter X Use packaging to bring down shipping rates

- Chapter XI Use the United States Postal Service (USPS) for last-mile delivery

- Chapter XII Leverage lower 3PL parcel rates for transportation savings

- Chapter XIII Make strategic use of regional carriers

- Chapter XIV Shift inner-zone express shipments to a more economical ground service

- Chapter XV Offer customers multiple shipping options

- Chapter XVI Match delivery service with the right carrier

- Chapter XVII Invest to retain warehouse workers

- Chapter I Establish productivity standards

- Chapter XIX Improve worker training to hike productivity

Share sales forecasts to improve labor planning

What’s the biggest driver of warehouse costs these days? Labor. So, it makes good sense to consider sales projections when planning warehouse labor requirements. Unfortunately, many brands do a terrible job sharing upstream data on sales forecasts and upcoming promotions with their downstream logistics teams and/or 3PL partners.

That results in a slew of problems:

● Understaffing and unhappy customers when orders can’t be processed on time

● Increased labor costs from overtime and extra shifts to meet unexpected demand

● High worker turnover linked to a stressful, unpredictable work environment.

● Inaccurate orders and costly rework resulting from the need to hire ill-trained temporary workers to fill staffing gaps

Bottom line: Fix this communication gap and you can reduce labor costs by at least 10%.

Conduct periodic distribution network modeling

Your base of customers – who they are, where they are – is different than it was 5 years ago, or even last year. When the design of your distribution network fails to account for shifts in end-market consumption, you overspend — by a lot.

Here’s an example. Many companies stick with a single-DC strategy for national distribution despite enormous sales growth. The downside?

● Lots of costly, high-zone parcel shipments

● Lost business from customers seeking faster delivery

● Risk of business interruption (Can your business survive if your single facility must shut down due to a natural disaster, pandemic or other reason?)

The answer is a distribution network modeling exercise to determine the optimal number of warehouses you should have and where they should be located to deliver the best service at the lowest cost.

NOTE: A fulfillment 3PL that operates a national network of fulfillment centers can let you easily expand or change facilities as your business grows and changes.

Bottom Line: An optimized distribution network can yield 7-figure savings for high-volume B2C shippers. One supplement brand shaved a million dollars off a $50 million freight spend after a modeling exercise determined it should add a second DC to lower parcel costs.

Integrate B2C and B2B fulfillment operations

If you use separate DCs for retail distribution and D2C fulfillment, the redundant costs — for inventory, buildings, systems and labor — are simply not sustainable. Sure, the operational requirements of direct-to consumer pick and pack are vastly different than retail replenishment, with its emphasis on bulk shipping and routing guide compliance. But you can satisfy those requirements in a single facility with the right systems and warehouse design.

NOTE: If you decide to outsource your omnichannel distribution, keep in mind that a 3PL with experience with one channel does not mean the logistics provider has the know-how to professionally handle full omnichannel fulfillment services.

Bottom Line: Most brands have adopted an omnichannel fulfillment model, but those that have not can easily achieve 6- or 7-figure savings.

Embrace data

The same brands that are sponges for data on sales trends and consumer preferences simply don’t dig into operational and fulfillment-related data with equal vigor — even though it’s one of the best ways to identify leaking profits. Questions to explore:

Receiving operations

● Did the orders arrive when the vendor said they would and in compliance with your requirements?

● Were the orders complete or were there regular overages or shortages?

Labor efficiency

● What’s the historical relationship between labor costs and total throughput, and are you getting more or less efficient?

● Do labor plans sync with historical order volume patterns for peak season?

With the right tools, you don’t need to be a data scientist to do the number crunching and analysis. Think about investment firms like Schwab or Fidelity. They have tools that allow investors to do very complex analyses and display results in clear charts and graphs. You should have access to similar tools.

Bottom Line: Take the time to mine data you’re already measuring.

Optimize your picking strategy

The wrong picking method can result in order pickers wasting precious time traveling around the warehouse searching for products or creating traffic jams that slow the picking process.

In a manual picking environment, DC operations employ five primary picking methods — discrete picking, batch picking, cluster picking, zone picking, and wave picking. Each method has its pros and cons. Some allow for easy training of temp workers, but aren’t very efficient for getting orders out the door quickly. One method is wellsuited to high-volume orders for small-sized items, while another is better for retrieving large items.

Bottom Line: Choosing the right pick method for your business can easily drive a six-figure annual labor savings. If you lack the internal resources to do this, a knowledgeable 3PL or consultant can help you make the smart picking choice for labor efficiency.

Deploy basic automation to reduce labor costs

You don’t have to spend big bucks on highly automated systems to achieve efficient eCommerce fulfillment. By taking advantage of basic automation tools, you can avoid paying workers to perform rote tasks.

● Using box erectors can reduce cost per box by 70 percent and increase box assembly throughput from 3 to 15 boxes per minute

● An automated box taping machine can free up warehouse associates while reducing tape waste

● Label applicators can free up workers from sticking a label on every item

Bottom Line: This type of low-level automation requires limited capital and, for higher-volume operations, delivers an ROI within one year.

Use cobots for transporting goods in the warehouse

Like we said earlier, labor is your biggest warehouse expense and right now 50% of what you pay warehouse workers is for walking between product aisles and packing stations. Collaborative robots (cobots) solve that problem.

By transporting orders to and from pick aisles, cobots enable a 2x–3x increase in picking productivity. Cobots also improve associate satisfaction and retention by reducing the physical demands of the job. That’s a huge advantage in a role where the yearly turnover rate is 43%.

Bottom Line: A Forester study of one robotics vendor found that cobots improved pick productivity by 100% while reducing picking error by 25% and the need for overtime pay by 15%. And you don’t have to invest millions to realize these benefits. A “Robots as a Service” financing model lets you implement almost immediately.

Improve slotting to reduce labor expenses

One often overlooked and underrated strategy for labor savings is slotting, which is the process of organizing inventory in a warehouse to minimize space requirements and reduce picker travel time. Efficient slotting lets fewer workers pick more orders, more efficiently by, for instance:

● Putting promoted or high-volume SKUs in forward-pick areas

● Creating adjacent locations for products that often sell together

● Placing fast-movers in locations that allow picking without bending or reaching

The issue isn’t that warehouse operators don’t do slotting, but that they don’t do it often enough. Typically, slotting happens at the onset of a project. But over time the volume changes or the SKU mix changes, and no slotting adjustments are made. Labor costs creep up, but very gradually, and no one attributes the increase to poor organization of inventory.

Bottom Line: Placing all your inventory in its optimal location results in efficient receiving, picking, and shipping. The annual labor savings from optimal slotting can be as much as 6 figures for higher-volume order fulfillment operations.

Automate inventory counts with drones

Despite the use of warehouse management systems, it’s still necessary to check that what is on the screen is really what’s on the shelf. Currently, you’re paying people to do that counting work and it’s a time-consuming and error-prone process.

Drones speed up the process and provide more reliable counts. A camera on the drone can read product barcodes, count cases, and even measure temperatures. Depending on the number of bins in a warehouse aisle, the drone can scan all products in an aisle in under 4 seconds.

Using drones to count on-hand inventory is not only faster, it’s cheaper than using a team of humans. A single drone can conduct a complete inventory count in a 25,000-square-foot area in 4 hours.

Bottom Line: For brands with large inventories, drone technology can deliver mistake-free inventory counts while eliminating labor costs linked to periodic cycle counts and multi-day annual physical inventories.

Use packaging to bring down shipping rates

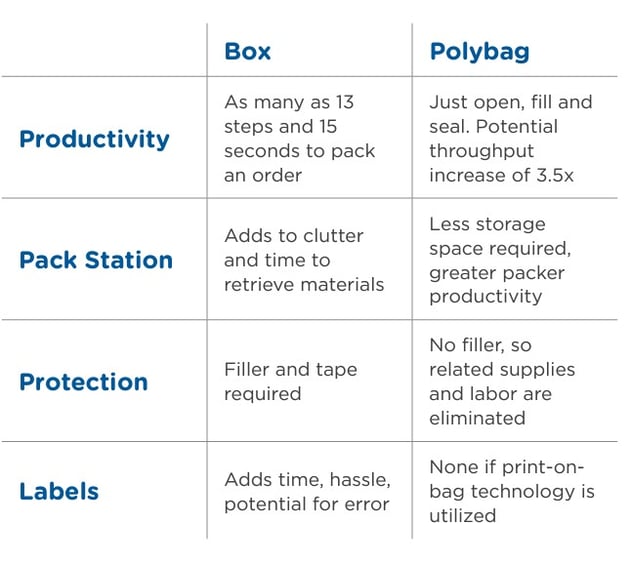

Are some or all of your products smaller and lightweight? If you’re shipping these items in boxes, there could be a tremendous opportunity to cut costs by shipping in polybags instead.

Polybags help you win at the dimensional weight pricing game. By minimizing package size, bags eliminate unnecessary dim weight charges as well as packing material.

Besides saving on shipping costs with bags, you’ll also cut labor costs. That’s because the number of steps involved in packing orders into polybags is substantially lower than packing into boxes. We’ve seen process steps go from 13 to 3 with the switch to polybagging.

Bottom Line: Going from bag to box can yield substantial savings for many brands shipping small but sturdy products. One such brand cut well over a million dollars in combined shipping, labor and packaging material costs by switching from box to bag for smaller, lightweight items.

Use the United States Postal Service (USPS) for last-mile delivery

Yes sir, the postal service can bring big savings when it handles the last-mile trip to the consumer’s door, even if you use UPS or FedEx for the line haul. Using a practice known as parcel consolidation, you can ship a package close to your destination with your parcel carrier or consolidator, but then use USPS for the final mile to avoid home-delivery surcharges and other costs. FedEx (SmartPost), UPS (SurePost) and UPS Mail Innovations all work with the postal service to capitalize on the fact that USPS already delivers to homes 6 days a week.

This strategy lets USPS handle the final delivery of lightweight packages, while avoiding all the various hubs and hand-offs within the USPS network that make the system inefficient.

Bottom Line: Save up to 40% over parcel carrier only deliveries.

Leverage lower 3PL parcel rates for transportation savings

B2C brands that outsource warehouse fulfillment do so mainly to focus on their core business. They don’t want to run warehouses and invest in costly fulfillment systems and automation. But one of the biggest potential advantages to outsourcing order fulfillment is actually freight savings.

Because 3PLs tend to manage parcel delivery for many brands, they can aggregate that total freight spend when negotiating rates with parcel carriers and then pass on the savings to you.

Bottom Line: The largest-volume shippers may see little to no savings from this strategy because they have good rates directly negotiated with the carrier. But small and mid-sized brands can cut their parcel spend 10% or more by shipping under the parcel account of a 3PL with better rates.

Make strategic use of regional carriers

We get that you may be hesitant to use regional parcel carriers because of the administrative complexity that comes with a broader base of carriers. Plus you don’t want to risk shipping discounts by divvying up your freight spend. But there may be benefits to adding regionals to your carrier mix.

You can often get lower freight rates from regionals who can provide cost savings over national carriers for next-day and two-day service in their service territory. So, for instance, you might consider a regional partner to service a delivery area around one of your main fulfillment centers.

Plus, there are fewer surcharges. That’s because regionals typically charge less for peak, rural, residential, and weekend deliveries.

Best of all, regionals offer faster delivery, and their on-time delivery rate for next-day and same-day delivery averages 99%.

Bottom Line: Although regional parcel carriers can’t replace the Big 3 for national distribution, they offer an excellent alternative in times of rising rates and capacity constraints. Use of regional carriers to handle a niche category (e.g., oversized) or region (e.g., Greater Dallas) can save up to 15% over major parcel carriers for that specific niche.

Shift inner-zone express shipments to a more economical ground service

Say your customer wants priority service. Do you know there’s a way to cut costs if you have a fulfillment center close to the ship-to address and keep the customer happy?

We’re talking about shipments within Zones 1, 2 and 3. For instance, take a shipment from Dallas to nearby Waco that may have used express service. You can shift to more economical ground home delivery service and still meet a 2-day delivery requirement. Customers don’t care how you get the order there, only that it arrives on time.

Bottom Line: By shifting inner-zone shipments to ground service, you can save $7 to $20 per package. That amounts to 30%–60% annually for packages shipping to zones 1–3.

Offer customers multiple shipping options

We all know that consumer expectations are becoming more and more speed-driven as 2-day, next-day, and even same-day shipping become more ubiquitous. But most consumers still prioritize delivery cost over speed.

You can increase your chances of satisfying all customers by offering shipping options with varying costs and transit times. While some customers want to pay for express shipping, others are willing to wait to get their order free or at a heavily reduced shipping expense.

Bottom Line: Provide online buyers more shipment options as there’s the potential to save 10–15% on shipping costs. In fact, by providing different delivery options, you could potentially have the customer pay for expedited services, thereby avoiding the entire delivery expense.

Match delivery service with the right carrier

Just as brands can get locked into using a single parcel carrier, they can lock into a specific service, as well. There are a wide variety of services available across parcel carriers, each with characteristics that may make it a more cost-effective option for some of your shipments.

For instance, you may love USPS Priority Mail, but for certain types of shipments another option could give you that exact service level for 25 percent less. One supplement company we know was shipping a high volume of lightweight packages nationally from two warehouses and paying significant surcharges for fuel, residential delivery, and rural delivery. A shift to another parcel carrier avoided the delivery surcharges, except for fuel, and saved as much as $8 per package.

Bottom Line: By matching your shipping requirements with the right carrier and service, you’re looking at a savings potential of 5–10%. If you are partnered with the right 3PL, it should have an excellent knowledge of the shipping options and be advising you accordingly.

Invest to retain warehouse workers

Right now, quality warehouse associates are hard to find, and even harder to keep — especially in the fast-paced environment of eCommerce fulfillment.

Stabilizing your workforce must be job one. If you can do that, higher levels of productivity, work quality, and customer satisfaction will follow. Warehouse worker turnover is 43%, on average, in the U.S. High associate turnover means more errors from less experienced workers, and each error erodes customer confidence.

Besides offering more money, what else can you do to keep your workers?

● Start listening to them and have your managers do monthly check-ins. A simple “thank you” for a job well done goes a long way.

● Offer flexible scheduling. Post-pandemic workers covet their time. Flexibility is a powerful form of compensation for young parents and older workers alike.

● Provide a clear path for advancement. Just like you, associates want to get ahead, assume more responsibilities, and earn more. If you treat workers like replaceable cogs in the machine, that’s what they’ll become.

Bottom Line: We estimate the total cost of losing a productive associate to be $8,500 or more. If you keep 25 workers you otherwise would have lost, that’s over $200,000 toward a much healthier bottom line.

Establish productivity standards

Many companies, including their 3PLs, don’t do a good job measuring warehouse worker productivity. As a result, unproductive associates fly under the radar, and you have no real sense of what your throughput could or should be. By investing to create fair and accurate productivity standards and making those visible across all associates, you’ll see a sharp rise in throughput along with lower labor costs.

An ideal set of pick and pack productivity standards can be developed by combining time studies on existing processes, input from warehouse management software, and feedback from management and warehouse associates.

Bottom Line: Studies show that associates, once informed of a target, want to meet or beat it. It’s human nature, and it’s why facilities that establish and monitor pick and pack productivity increase throughput by 10–15%.

Improve worker training to hike productivity

Excellent training for warehouse associates is far from a luxury in today’s labor market, where workers are more elusive and expensive than ever. Brands that hope to scale must hold on to, and make the most of, what they’ve got.

Companies that take shortcuts with training look at it the wrong way. They see training as a cost rather than an investment. As such, they fast-track training to get new workers and temps on the floor as soon as possible to get orders out the door.

But poorly trained staff make more mistakes and take much longer to become 100 percent productive. With this training philosophy, you’ll effectively double your labor costs because you’ll have four people operating at 50% productivity in place of two people who are 100% productive.

Bottom Line: When you invest in smarter training, you improve retention, increase productivity, and reduce error-related costs.

HEALTHIER FULFILLMENT LEADS TO A HEALTHIER BOTTOM LINE

There you have it, 19 pro tips to cut costs and create a more optimized warehousing and shipping operation. Implementing even one or two of these outlined strategies can drive profit improvements for margin-conscious brands.

Our advice: start small. Identify the low-hanging fruit and initiate only those projects you have the resources to tackle and complete.

For a more comprehensive fulfillment fitness overhaul, consider outsourcing to a 3PL that brings best practice experience in D2C distribution — including compliance, quality assurance, and the complex kitting processes that brands sometimes require.

Today, most brands differentiate not based on product or price but on the overall customer experience. Order fulfillment is at the heart of this customer experience. Consider being the catalyst your company needs to create the leanest, fittest order fulfillment operation possible.

Get a Quote

Ready to get started? We are here to answer your questions